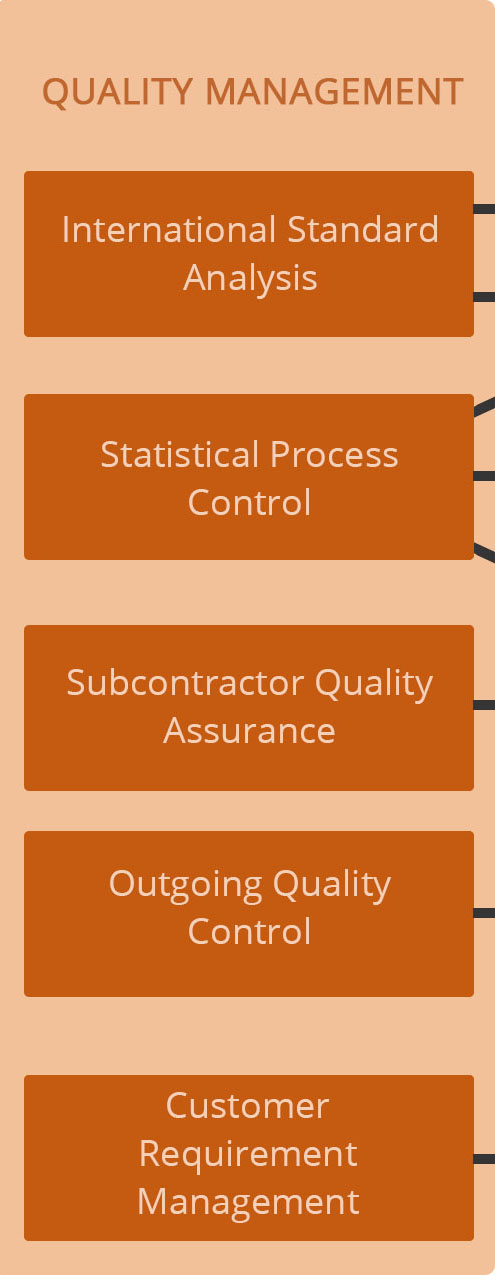

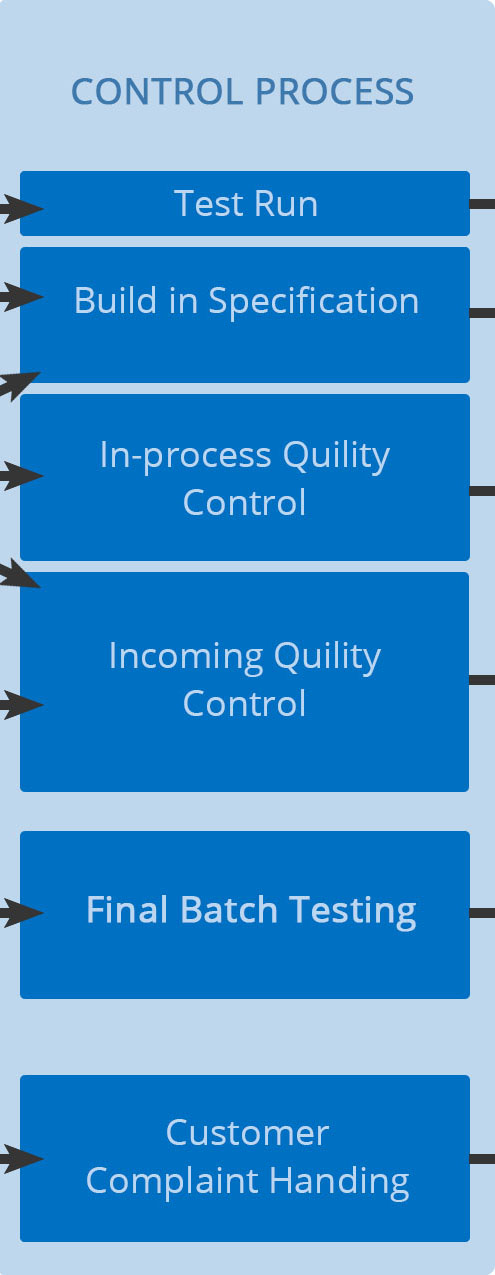

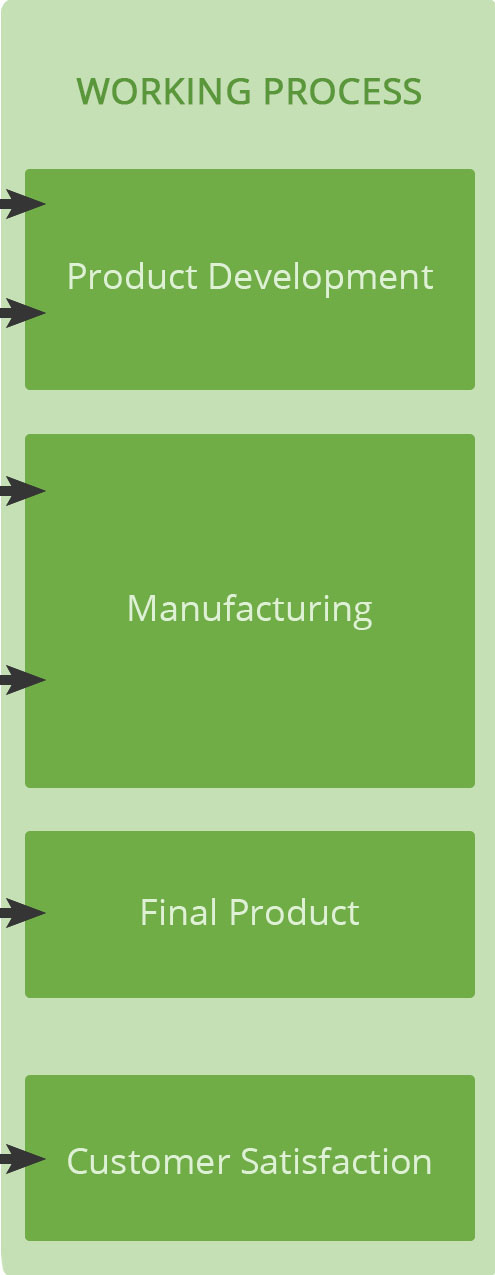

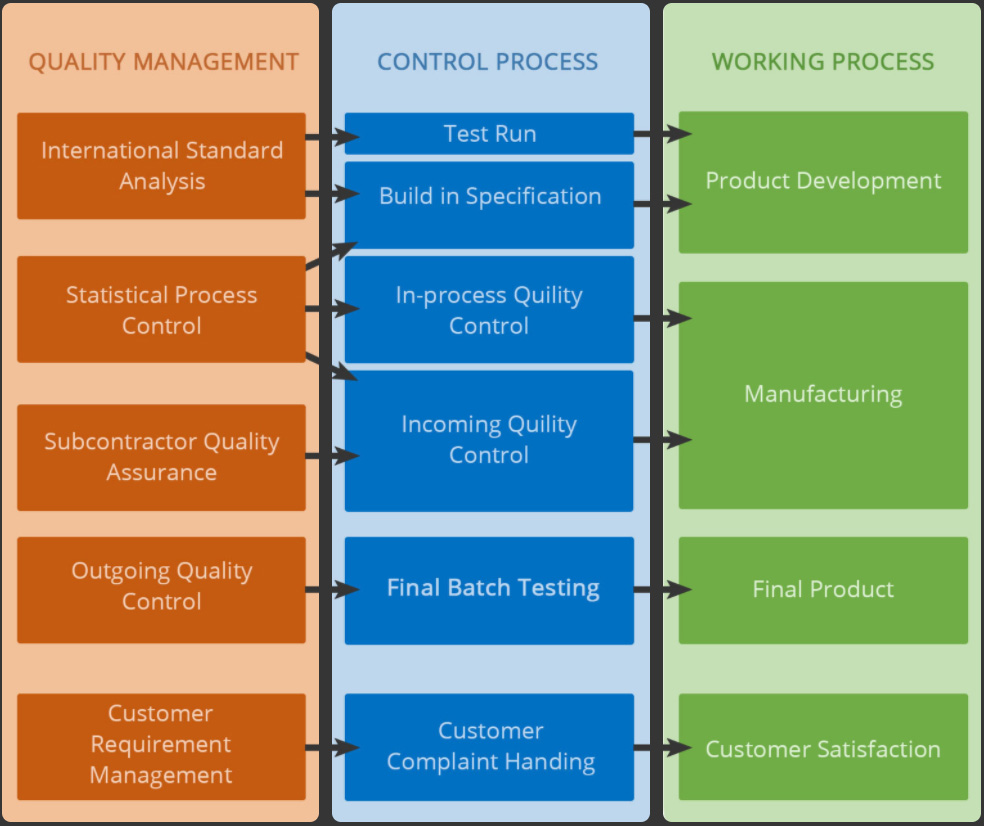

All-Logic Quality System meets all the requirements for the international standards and quality assurance programs. Our system includes both in-process inspection & final batch inspection .

All-Logic believes the inspection of all incoming

materials is a prerequisite for assuring stable quality

products. At this stage, our QA department will

immediately eliminate any quality defects before

proceeding to the next production process.

All-Logic believes the inspection of all incoming materials is a prerequisite for assuring stable quality products. At this stage, our QA department will immediately eliminate any quality defects before proceeding to the next production process.

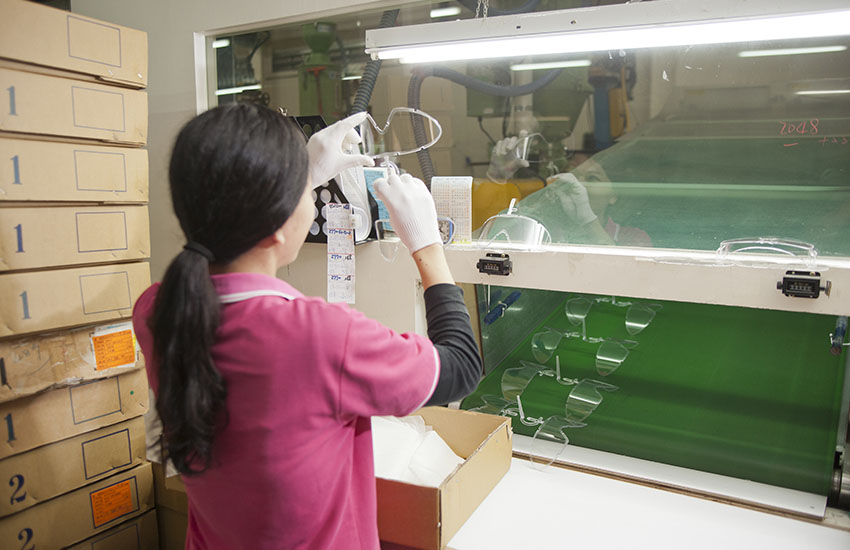

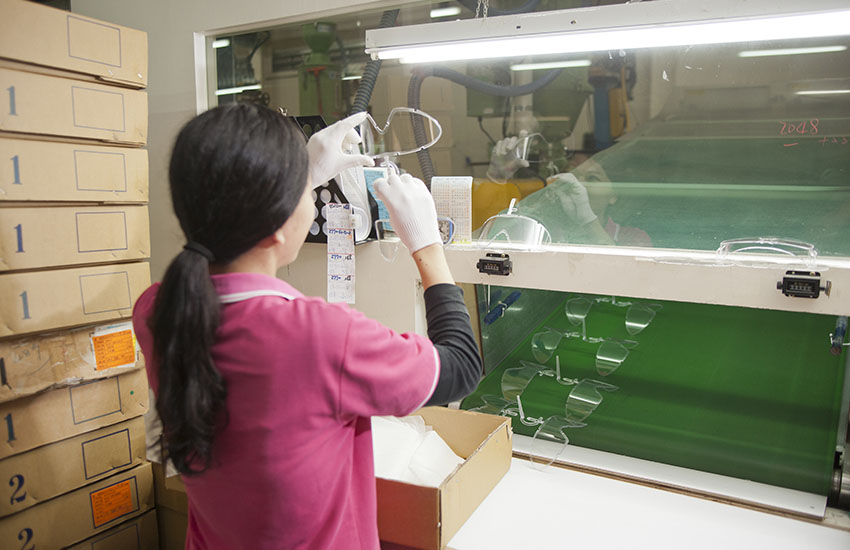

The self-inspection in the process is carried out by each of our

on-site coworkers. Products are continuously inspected during

the manufacturing process and it’s overseen by each

department supervisor, as well as roving inspectors.

The self-inspection in the process is carried out by each of our on-site coworkers. Products are continuously inspected during the manufacturing process and it’s overseen by each department supervisor, as well as roving inspectors.

Our QA department will make sure all batches of

products are fully tested to the relevant country

standards. In the meantime, random sampling tests

will also be conducted in order to check for correct

marking and packaging prior to dispatch.

Our QA department will make sure all batches of products are fully tested to the relevant country standards. In the meantime, random sampling tests will also be conducted in order to check for correct marking and packaging prior to dispatch.

Full production and inspection records are classified by categories

and kept for 10 years in our document management center.

Full production and inspection records are classified by categories and kept for 10 years in our document management center.